#Linear Guide [Linear Guide Rail] Demand

Explore tagged Tumblr posts

Text

0 notes

Text

Needle vs. Cylindrical Rollers: Which is Better for Linear Bearings?

You may be aware with rotary needle roller bearings, which are widely utilised in automotive and industrial power transmission applications because to their compact size and great load carrying capacity. But did you know that certain linear bearings employ needle rollers?

Linear bearings were initially used in non-recirculating linear guides, but manufacturers have lately produced recirculating contoured rail guides with needle roller bearings to suit the ever-increasing demands for stiffness and smoothness of movement.

How are needle rollers different from Cylindrical Needle Rollers?

The length-to-diameter ratio of cylindrical rollers distinguishes them from needle rollers. To qualify as a needle roller, the roller's length must be at least three times its diameter. In actuality, needle rollers can have length-to-diameter ratios ranging from 3:1 to 10:1, whereas cylindrical rollers have ratios smaller than 3:1.

The typical load-carrying components of linear bearings, both recirculating and non-recirculating, are balls or cylindrical rollers, both of which give high load capacity, minimal friction, and strong stiffness for linear motion applications. However, as cylindrical rollers provide a "step up" in performance above balls, particularly in terms of load capacity and stiffness, needle rollers outperform cylindrical rollers in several ways.

One of the primary reasons for employing needle rollers in radial bearings is their small size; nevertheless, in linear bearings, the primary advantages of needle rollers over balls or Cylindrical Needle Rollers China are higher load capacities and greater stiffness. This is because needle rollers spread the load among more, smaller rollers, each of which has a bigger contact area than a cylindrical roller. This lessens the pressure per roller, allowing the bearing to withstand greater loads.

Needle rollers give smoother motion in two ways when used with recirculating profiled rail bearings. First, needle rollers have greater dynamic friction than balls or cylindrical rollers from Cylindrical Needle Rollers Supplier. Although higher running friction is a disadvantage in some applications, it can be advantageous in high-load, high-rigidity linear guides because it dampens vibrations caused by external forces. And, as the load is distributed over more, smaller rollers, the vertical pulsation of the bearing generated by roller motion is decreased.

Follow our Facebook and Twitter for more information about our product.

#Cylindrical Needle Rollers#Cylindrical Needle Rollers Manufacturer#Cylindrical Needle Rollers Supplier#Cylindrical Needle Rollers China

1 note

·

View note

Text

Vinyl Fencing Cost: Pricing Breakdown and Key Factors

Vinyl Fencing Cost Overview

Vinyl fencing is a popular choice for homeowners looking for a durable, low-maintenance, and visually appealing alternative to wood or metal fences. Unlike traditional wood fences that require regular painting and sealing, vinyl fencing is weather-resistant, long-lasting, and available in a variety of styles. However, the cost of vinyl fencing varies depending on several factors, including material quality, fence length, installation method, and additional customization options. This guide breaks down everything you need to know about vinyl fencing costs to help you make an informed decision.

How Much Does Vinyl Fencing Cost?

The cost of vinyl fencing depends on various elements such as the type of fence, installation costs, and local labor rates. On average, homeowners can expect to pay between $15 to $45 per linear foot for materials and an additional $5 to $15 per linear foot for professional installation.

Vinyl Fencing Material Costs

Vinyl Thickness: Thicker panels cost more but provide better durability.

Style & Design: Decorative designs, latticework, and textured vinyl increase the price.

Color Options: Standard white vinyl is cheaper, while custom colors and wood-look finishes are more expensive.

Additional Features: Post caps, reinforced panels, and UV-resistant coatings add to the cost.

Installation Labor Costs

Soil Conditions: Rocky or uneven terrain may require additional labor and equipment.

Fence Height: Taller fences require more material and effort to install.

Local Labor Rates: Costs vary by location and demand.

Complexity of the Design: Custom fence designs require more time and skill to install.

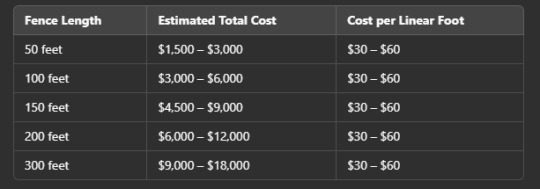

Cost Estimates by Fence Length

Below is an estimate of vinyl fencing costs based on the total fence length:

Additional Costs:

Gates: $200 – $1,500 (depending on size and style)

Decorative Post Caps: $50 – $200 per post

Custom Hardware & Latches: $200 – $500 per feature

Permit Fees: $50 – $200 (varies by location)

Vinyl Fencing Types and Costs

Different vinyl fence styles cater to different needs, from security and privacy to decorative appeal. Here’s a breakdown of common types:

1. Privacy Vinyl Fence

Cost: $25 – $45 per linear foot

Best For: Backyard privacy, noise reduction, pool enclosures

Features: Solid panels with interlocking sections for complete privacy

2. Post-and-Rail Vinyl Fence

Cost: $15 – $25 per linear foot

Best For: Farms, ranches, and large properties

Features: Open horizontal rails with minimal materials for a rustic look

3. Semi-Privacy Vinyl Fence

Cost: $20 – $40 per linear foot

Best For: Homeowners who want some airflow while maintaining partial privacy

Features: Spaced pickets or louvers that allow light and air to pass through

4. Vinyl Picket Fence

Cost: $15 – $35 per linear foot

Best For: Front yards, gardens, and decorative landscaping

Features: Shorter height with traditional or modern styles

Factors Affecting Vinyl Fencing Costs

1. Fence Height and Design Complexity

Taller fences (over 6 feet) require more material and labor, increasing costs.

Custom designs like lattice tops and wood-textured vinyl panels add to expenses.

2. Terrain and Site Preparation

Uneven or rocky ground may require additional excavation or leveling.

Stepped or racked fences may be needed for sloped yards, increasing costs.

3. Permits and Local Regulations

Many areas require permits for fences exceeding a certain height (typically 6 feet).

HOA (Homeowners Association) rules may dictate fence styles and colors.

4. Climate Considerations

In extreme climates, UV inhibitors and impact modifiers can prevent cracking and warping but add to the cost.

Reinforced posts may be required in high-wind areas.

5. Customization and Accessories

Lattice Tops & Decorative Caps: Add visual appeal but increase costs.

Reinforced Panels: Improve durability, especially in areas with strong winds.

Lifespan and Maintenance of Vinyl Fencing

Vinyl fences are known for their durability and long lifespan. A well-maintained vinyl fence can last 20–30 years without fading, rotting, or requiring major repairs.

Maintenance Tips:

Clean with soap and water annually to prevent dirt buildup.

Inspect for shifting posts or loose panels after storms.

Avoid pressure washing, as it may damage the surface.

Environmental Impact of Vinyl Fencing

Many modern vinyl fences are made from recycled PVC, reducing their environmental impact. Unlike wood fences, vinyl does not require harmful chemical treatments or frequent staining. Some manufacturers specialize in eco-friendly vinyl fencing made from post-consumer and post-industrial recycled materials.

Final Thoughts: Is Vinyl Fencing Worth the Cost?

Vinyl fencing is a long-term investment that offers low maintenance, durability, and aesthetic appeal. While the upfront cost may be higher than wood or chain-link fences, the lack of ongoing maintenance makes it a cost-effective choice in the long run.

If you’re considering installing a vinyl fence, be sure to compare quotes from multiple contractors, check for bulk discounts, and factor in any customization options that suit your needs.

Looking for more fencing guides? Check these out:

How Much Does Fencing Cost Per Acre?

Is Hog Wire Fence Cheaper Than Wood?

11 Glass Fencing Ideas for Backyards and Pools

Do you have any experience with vinyl fencing? Share your thoughts in the comments below!

Write something...

#backyard fence#fence types#fencing cost#fence#vinyl fences#vinyl fence cost#vinyl fence#fence cost#home fencing

0 notes

Text

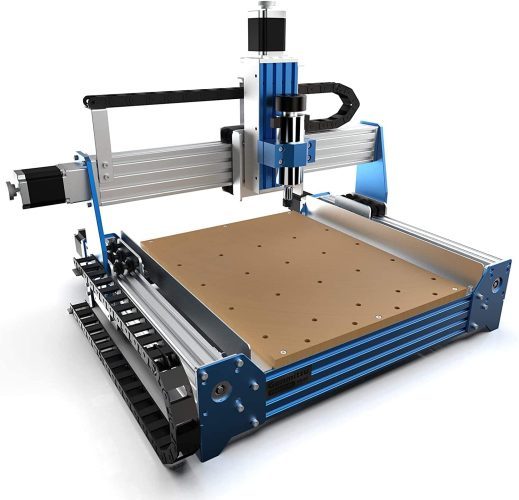

1325 CNC Wood Cutting Machine 4×8

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

Our 1325 CNC machine is one of our popular and best-selling machines. It is good at cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal, and other materials.

CNC Wood Cutting Machine 4×8

This 1325 cnc wood cutting machine can change 12 different tools automatically. It is very suitable for the people who do complex work and change different tools frequently. This machine is provided with a push device and can push materials after cutting or engraving.

High Precision Cutting Best Selling CNC Machine For 4×8 Small CNC Machine

The 4×8 CNC machine XYZ axis Taiwan Hiwin square rail makes the gantry and spindle moving at high speed with high precision. CNC kit 4×8 adopts Hiwin square rail with high rigidity and very durable. XY axis German Helical rack and pinion are directly coupled to the stepper motor and pinion. This 4×8 CNC router cheap configuration ensures that the accuracy is less than ±0.03mm when the max 4×8 work table speed is 20,000mm/min.

Stable, Stronger And More Durable Structural Design Of CNC Machine Table 4×8

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

Long Time Operation With High-Power Stepper Motor Of Cheap CNC Router

Stepper motor and driver do not require regular maintenance. This not only reduces maintenance downtime but also spindle is able to run normally for a long time. Coupled with the fast working speed, the CNC machine 4×8 efficiency is greatly improved.

Compatible With Any Advanced Software For 4×8 CNC Wood Router

Software including Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks is run on the system of CNC table 4×8. You can use the CNC wood router 4×8 quickly without wasting the cost of training labor. This is simple and efficient for you.

Features CNC Wood Cutting Machine

1. Heavy duty frame. The frame is longer and much stronger than normal CNC routers.

2.Taiwan 1000w SYNTEC servo motor with Japan SHIMPO reducer. It adopts full closed loop and has brake function on Z axis. It provides constant position feedback, bigger power and smooth contentious motion.

3. Linear type tool change magazine under gantry. It can change 12 different tools fast.

4. Y axis adopts #30 Taiwan square linear guide. While X and Z axis adopt #25 square linear guide. 2M helical rack is used to ensure the high-speed and stable operation of the machine, and also ensure a higher processing accuracy.

5. ATC air cooling spindle. Max. speed can be 24000RPM. With ISO30 tool holder, it can use 20mm bits at max.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal wood cutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Heavy duty CNC router is good for complex processes and long time work, such as:

Wood door, furniture making; MDF, Poly wood cutting;

Hardwood engraving & carving;

Big scale woodworking;

Soft metal, plastic, acrylic, foam engraving & cutting, etc.;

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available.Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

0 notes

Text

GTH series | Built-in guide Rail type

youtube

Toyo Robotics is proud to present the GTH Series, our latest innovation in linear motor robots with a built-in guide rail. Engineered for precision, durability, and seamless integration, the GTH Series is set to redefine your automation experience.

🔹 High Precision: Achieve ultra-high accuracy with a repeatability of ±0.005mm.

🔹 Integrated Guide Rail: Built-in guide rail design ensures smooth and stable movement.

🔹 High Speed: Speeds up to 1600 mm/s for fast and efficient operations.

🔹 Load Capacity: Capable of handling loads up to 110 kg.

🔹 Robust and Durable: Designed for long-term reliability in demanding industrial environments.

Upgrade your automation processes with the GTH Series and experience unparalleled performance. Discover the future of robotics with Toyo Robotics!

#GTHSeries#LinearMotorRobot#BuiltInGuideRail#Automation#Robotics#PrecisionEngineering#Efficiency#Youtube

0 notes

Text

Linear Motion Products: Empowering Industrial Precision

In the modern industrial landscape, precision, efficiency, and reliability are key components that drive innovation and operational success. Industries ranging from automotive manufacturing to aerospace and automation heavily rely on equipment and machinery that ensure accuracy and smooth operation. One of the fundamental elements behind these systems is linear motion products. These high-performance components allow for smooth linear movement, contributing to everything from production lines to heavy-duty machine tools.

At Jai Krishna Bearing House, we take pride in being a trusted name in the industrial bearings sector, offering premium-quality linear motion products. Our company stands as one of India's leading importers and exporters of industrial bearings, including linear bearings and motion products, while also providing authorized dealer services across the country. With a strong reputation for delivering reliable solutions, Jai Krishna Bearing House has been an indispensable partner for industries looking to enhance precision and streamline their operations.

What Are Linear Motion Products?

Linear motion products consist of various components that facilitate controlled movement in a straight line. Unlike rotary motion, which follows a circular path, linear motion involves the back-and-forth movement along a straight trajectory. These components are widely used in applications where precision, low friction, and durability are critical.

Some of the most common linear motion products include:

Linear Bearings: These bearings are designed to support and guide movement in a straight line, reducing friction and wear. They come in several types, such as ball bearings and roller bearings, and can support loads in both horizontal and vertical directions.

Linear Guides: Also known as guide rails or linear rails, these are mechanical devices that provide smooth and accurate movement of an object along a straight path. Linear guides are essential in CNC machines and automation systems.

Ball Screws: Ball screws are used to convert rotary motion into linear motion with minimal friction. They are widely employed in high-precision applications like CNC machines, robots, and medical devices.

Linear Actuators: These are motorized devices that generate linear movement. They are often used in robotic systems, conveyors, and various automation tasks.

Linear Bushings: These are small, cylindrical components that guide linear shafts in their movement, minimizing friction. Linear bushings are used in equipment where accuracy and smooth operation are essential.

Linear Motors: A type of electric motor that produces linear motion directly without the need for mechanical conversion from rotary motion. These are used in applications requiring high-speed, precise movement.

At Jai Krishna Bearing House we offer a wide range of linear motion products designed to meet the demanding requirements of industries seeking high performance and efficiency.

Importance of Linear Motion Products in Modern Industry

Linear motion products are integral to the success of numerous industrial operations. They are used in applications where accuracy, speed, and durability are essential to maintaining productivity and ensuring the quality of end products. Here's how linear motion components enhance industrial performance:

Precision and Accuracy

Linear motion products are critical in environments where even the smallest deviation can lead to errors and inefficiencies. In the manufacturing and automation industries, where high accuracy is required, linear motion components ensure smooth and precise operations. For example, CNC machines rely on ball screws and linear guides to produce exact cuts and movements, ensuring that components are manufactured with exacting standards.

Enhanced Durability and Reliability

Industrial equipment often operates under high-stress conditions, where wear and tear can cause significant downtime and costly repairs. Linear motion products are designed to handle extreme situations, ensuring longer lifespans and reduced maintenance costs. Components such as linear bearings and actuators are engineered to withstand heavy loads, high speeds, and harsh environments.

Increased Efficiency

Linear motion products contribute to the efficiency of industrial systems by reducing friction and wear, ensuring smooth operations. Whether it's a conveyor belt in a manufacturing plant or a robotic arm in an assembly line, linear motion components minimize energy consumption and maximize the overall efficiency of machines. This results in faster production times and optimized workflows.

Flexibility in Application

One of the biggest advantages of linear motion products is their versatility. From medical equipment that requires delicate movements to heavy machinery in construction, these components can be adapted for use in various industries. They are used in sectors like automotive, electronics, aerospace, food and beverage processing, and material handling, to name a few.

Jai Krishna Bearing House: Your Trusted Partner for Linear Motion Solutions

At Jai Krishna Bearing House, we are dedicated to offering the highest quality linear motion products that cater to the specific needs of industries across India and beyond. As an industrial bearings importer and exporter, our commitment to delivering premium solutions has helped us establish a strong reputation for reliability and performance. Here’s what sets us apart:

Expertise in Industrial Bearings: With years of experience in the field, we provide unparalleled knowledge and expertise in industrial bearings, including linear motion components. Our team of professionals understands the unique challenges faced by various industries and offers tailor-made solutions to meet those needs.

Comprehensive Product Range: From linear bearings and guides to actuators and ball screws, we offer a comprehensive range of linear motion products designed to enhance precision and durability in industrial applications.

Authorized Dealer Services: As an authorized dealer, we ensure that all our products are sourced from reputable manufacturers, guaranteeing quality and performance. Our strong partnerships with global brands allow us to offer competitive prices without compromising on reliability.

Global Reach: We export our products to various international markets, meeting the stringent quality standards demanded by industries worldwide. Our global reach enables us to stay at the forefront of innovation and offer our clients the best solutions available.

Conclusion

In today's competitive industrial environment, precision, durability, and efficiency are non-negotiable. Linear motion products play an essential role in ensuring that industries operate with the highest standards of performance and reliability. At Jai Krishna Bearing House, we are proud to be a trusted supplier of these critical components, helping industries across India and the world achieve their goals through our top-notch solutions. Jai Krishna Bearing House linear bearings, guides, or other motion products, our extensive product range and expertise are here to meet your needs and drive your operations forward

0 notes

Text

Multifunctional bushelling processing machine equipment quotation (What are the manufacturers of Gansu's mother row row row)

Considering that the winding line structure is entangled by manually performing fine copper lines, the outer diameter of the multi -core copper wire is small, the manual entanglement is time -consuming and laborious, and the problem of uneven entanglement is prone to occur. Low, uniform entangled, time -saving and labor -saving new bus.

The bus processing machine is mainly suitable for high and low voltage switch cabinets and transformer manufacturing industries, which are used to process various specifications of copper and aluminum busbar machine. As long as the user is on the corresponding processing unit, it can separate the rushing, cutting, and discount processing of the parent line, and the production efficiency is high. Multifunctional busilation processing machine equipment quotation

To give full play to the performance of the linear guide rail, it is necessary to choose the appropriate types and lubrication methods of lubricant according to the form, load, speed, etc. of the linear guide.

When the pilot overflow valve is unloaded, the pressure impact noise will occur due to the rapid decline in the pressure of the hydraulic circuit. The more high pressure and high -capacity work conditions, the greater the impact noise. This is due to the short loading time of the overflow valve and the hydraulic impact caused by the hydraulic impact. Due to the sharp changes in the oil flow, the pressure causes the pressure to change, causing the pressure to change, causing the stress, causing it The impact of pressure waves. The pressure wave is a small shock wave, which produces small noise itself, but as the oil is transmitted to the system, if it resonates with any mechanical parts, it may increase vibration and enhance noise. Therefore, when hydraulic impact noise occurs, it is generally accompanied by systemic vibration.

Multifunctional parent line processing machine equipment quotation Heavy machinery: downstream demand for heavy machinery industries, especially the demand for metallurgical equipment continued to recover. From January to June, the growth rate of fixed assets in the steel industry reached 6%, which was further increased from the growth rate of 0.2%from January-May. In June, the output of metal metallurgical equipment increased by 7%month -on -month, reflecting the continuous growth trend. Fixed asset investment in the mining industry still maintained a high growth of 24%from January to June, and the output of mining equipment was basically the same as the same period last year. Looking forward to the future, orders in the heavy machinery industry are expected to continue to improve. We are optimistic about heavy mechanical leading enterprises such as Taiyuan Heavy Industry.

Advanced and reliable rear material structure The beams of the rear gear structure and the left and right sidelines are based on aluminum profiles. Reduce the motion inertia of the rear material block. Show precision and reliable transmission. The transmission of the rear material uses the arc tooth synchronous transmission and the large guide precision roller screw and guide rail transmission, and the precision positioning of the rear gear is implemented.

By consulting information about the current status of domestic parent line machines, and deep into the first -line production to investigate the problems of existing homelines, it is believed that the domestic parent line processing machine is generally relatively backward, and it is difficult to meet the process requirements of new products. : Multifunctional busilation processing machine equipment quotation

Bending angle CNC, making it difficult to master the bending angle is very easy and convenient, with high accuracy. With memory function, the data of the processing workpiece can be transferred at any time. It is a prominent advantage that traditional methods cannot compare. The touch screen has the calculation function of the workpiece graphical angle (that is, the length of the graphical edge, and automatically generate the bending angle). By replacing the mold, the flowing stream can be flattened, standing, etc. can be made.

0 notes

Text

Unlocking Accessibility: The Rise of Home Stairlifts in the UK

In the intricate dance of daily life, our homes often present us with unexpected challenges. For some, the simple act of climbing stairs can transform into a Herculean task. As the concept of aging in place gains momentum, the demand for home curved stairlifts has surged, and the United Kingdom stands at the forefront of this movement.

The Soaring Popularity of Home Stairlifts

Imagine a world where ascending stairs is not a daunting feat, but a seamless glide. That's the reality that home stairlifts offer, and their popularity in the UK has skyrocketed in recent years. The charm lies in the simplicity – a device that transforms stairs into a comfortable journey, effortlessly overcoming the barriers that once confined individuals to specific floors of their homes.

Enhancing Independence: Home stairlifts are not just mechanical contraptions; they are liberators. They empower individuals to maintain their independence and autonomy, creating a ripple effect that positively impacts their overall well-being.

Compact Marvels: Picture a compact, unobtrusive companion waiting patiently on your staircase, ready to ferry you between floors with grace. Modern home stairlifts are designed with space efficiency in mind, seamlessly blending into the aesthetics of your home.

Navigating the Nuances: Understanding Home Stairlift Types

Home stairlifts aren't one-size-fits-all solutions; they come in various types, each catering to specific needs and staircase configurations. Let's embark on a journey through the diverse landscape of home stairlifts.

Straight Stairlifts: The Straightforward Solution

Straightforward Prowess: Straight stairlifts are the unsung heroes of simplicity, designed for stairs with a single, unbroken trajectory. They offer a straightforward solution for those with uncomplicated staircase layouts, ensuring a smooth and efficient ride.

Streamlined Elegance: Installing a straight stairlift is like adding a touch of streamlined elegance to your home. These devices are a testament to how simplicity can coexist with sophistication, seamlessly integrating into your living space.

Curved Stairlifts: Embracing the Complexity

Embracing the Curve: Life is seldom linear, and neither are all staircases. Curved stairlifts gracefully navigate the intricate twists and turns of curved stairs, ensuring that every inch of your home is accessible. They're the virtuosos of adaptability.

Tailored Precision: Picture a bespoke solution tailored to the unique contours of your staircase. Curved stairlifts are precision instruments, ensuring a snug fit that feels tailor-made. It's akin to having a personal chauffeur for your ascent.

Outdoor Stairlifts: Nature's Gateway

Conquering the Elements: The allure of the outdoors can now be enjoyed by everyone, irrespective of mobility challenges. Outdoor stairlifts are weather-resistant marvels, conquering the elements to grant access to gardens, patios, and more.

Nature's Gateway: An outdoor stairlift is akin to a gateway to nature, breaking down barriers that once kept individuals indoors. It's a testament to technology's ability to harmonize with the great outdoors, enabling individuals to enjoy the serenity of their surroundings.

The Heart of the Matter: Understanding How Stairlifts Operate

While the sleek design and adaptability of home stairlifts capture attention, understanding the mechanics behind these devices unveils the heart that beats within. Let's unravel the mystery and explore how these contraptions transform the seemingly impossible into a daily reality.

The Power of Rails: At the core of every stairlift is a meticulously crafted rail system. This unassuming yet crucial component serves as the guide, ensuring a secure and smooth journey up or down the staircase. It's like a trusted handrail, always there to offer support.

Whisper-Quiet Motors: Modern stairlifts operate with a near-silent grace, thanks to advanced motor technology. The ascent or descent is accompanied by a gentle hum, turning what could be a noisy disruption into a seamless, almost meditative experience.

User-Friendly Controls: Controlling a stairlift is as intuitive as it gets. With user-friendly controls often integrated into the armrest, users can effortlessly command their ascent or descent. It's like having the power of movement literally at your fingertips.

Making the Leap: Benefits Beyond the Obvious

Beyond the evident convenience, home stairlifts offer a myriad of benefits that extend far beyond mere mobility assistance. Let's delve into the often-overlooked perks that make these devices transformative additions to any home.

Preserving Dignity: Climbing stairs may seem trivial, but for individuals facing mobility challenges, it can become a source of frustration. Home stairlifts restore dignity, allowing individuals to navigate their homes without the need for assistance.

Stress Reduction: The daily grind is stressful enough without the added burden of struggling with stairs. Stairlifts eliminate this stress factor, offering a peaceful and unhurried means of moving between floors. It's a stress reduction therapy wrapped in a mechanical cocoon.

Family Harmony: The ripple effect of installing a home stairlift extends to the entire household. Family members can rest easy, knowing that their loved ones can effortlessly move about the house. It's a catalyst for harmony, fostering an environment where everyone can thrive.

The Price of Liberation: Investing in Accessibility

As with any transformative technology, the question of cost inevitably arises. While home stairlifts represent a significant investment, the returns in terms of improved quality of life are immeasurable. Let's explore the factors that contribute to the price tag and why the investment is well worth it.

Customization Comes at a Price: The intricacy of curved stairlifts and the need for customization contribute to their higher price compared to straight stairlifts. However, this extra cost ensures a tailored solution that seamlessly fits your home's unique layout.

Long-Term Value: Viewing a home stairlift as a long-term investment rather than an immediate expense reframes the cost perspective. The longevity of these devices, coupled with the priceless benefits they bring, makes them a wise financial decision in the pursuit of enhanced accessibility.

Comparing Costs to Alternatives: When weighing the cost of a home stairlift, it's essential to consider the alternatives. Moving to a single-story home or restructuring the existing staircase can incur significant expenses and disruptions. In comparison, a stairlift provides a cost-effective and non-intrusive solution.

The Road Ahead: Trends Shaping the Future of Home Stairlifts

As technology continues to evolve, so do home stairlifts. The future promises even more innovative solutions, seamlessly integrating with the evolving needs and preferences of homeowners. Let's peer into the crystal ball and explore the trends that are shaping the road ahead for home stairlifts.

Smart Integration: The era of smart homes is upon us, and home stairlifts are no exception. Imagine a stairlift that syncs with your daily routine, anticipating your movements and adapting to your preferences. It's the dawn of stairlifts that seamlessly integrate into the fabric of your smart home.

Design Fusion: As aesthetics play an increasingly significant role in home design, stairlifts are poised to become design statements in their own right.

In the grand symphony of life, the staircase should never be a daunting crescendo. With home stairlifts, every step becomes a graceful note, allowing you to compose your own melody of independence and convenience. From straight staircases to winding ones, the versatility of these contraptions is as vast as the dance floor itself.

So, if you find yourself hesitating at the foot of the stairs, wondering if you can conquer that daily ascent, remember – there's a stairlift waiting to whisk you away, making every journey a performance worth applauding. Embrace the elegance, revel in the convenience, and let the dance of home stairlifts elevate your life to new heights.

0 notes

Text

Linear Sliding Tables: An Overview

Linear Sliding Tables: An Overview Linear sliding tables are mechanical devices that provide linear movement and are widely used in touch screen production equipment, optical instruments, and other fields. In this article, we will discuss the basics of linear sliding tables, including their components, working principles, and applications.Get more news about linear sliding table suppliers,you can vist our website!

Components of Linear Sliding Tables A linear sliding table is mainly composed of a sliding table, guide rail, drive system, and control system. The sliding table is the part that moves along the guide rail, and the guide rail provides support and guidance for the sliding table. The drive system is responsible for driving the sliding table along the guide rail, and the control system is used to control the movement of the sliding table.

Working Principles of Linear Sliding Tables The working principles of linear sliding tables are based on rolling element bearings, plain surface bearings, and magnetic bearings. Rolling element bearings use balls or rollers to reduce friction between the sliding table and the guide rail. Plain surface bearings use a sliding surface to reduce friction, and magnetic bearings use magnetic fields to levitate the sliding table.

Applications of Linear Sliding Tables Linear sliding tables are widely used in various fields, such as manufacturing, robotics, scientific research equipment, and more. They are commonly found in applications demanding extreme precision and vibration isolation, such as semiconductor manufacturing equipment. Linear sliding tables can also be used in applications requiring high speed and acceleration, such as pick-and-place machines.

In conclusion, linear sliding tables are essential mechanical devices that provide linear movement and are used in a wide range of applications. They are composed of a sliding table, guide rail, drive system, and control system, and their working principles are based on rolling element bearings, plain surface bearings, and magnetic bearings. If you are looking for a device that can provide precise and reliable linear motion, a linear sliding table may be the right choice for you.

0 notes

Text

Circular Precision Track Systems Will Be Delivered To Ukraine

Circular precision track systems consist of circular tracks, precision bearings, and drive systems that enable controlled and accurate movement in circular paths.These systems typically are often used in various industries, including manufacturing, robotics, and transportation.

In manufacturing, circular precision track systems are commonly used in automated assembly lines, allowing components or products to move along precise circular paths for efficient processing. In robotics, these systems enable robotic arms or devices to move in circular motions with high precision, which is valuable in tasks such as welding, painting, or material handling. https://youtu.be/8Igb1WPw8yg In transportation, circular precision track systems can be found in applications such as amusement park rides, conveyor systems, and even some types of vehicles where circular motion is required. In recent years, Circular Precision Track Systems have gradually been recognized and widely applied in the manufacturing industry, promoting the transformation and updating of the entire industry. As a railway system technology, together with the transmission system, it can perform cyclic motion, reduce inter station flow rate, shorten production cycle, improve production efficiency, reduce personnel costs, and achieve automatic production. With market demand, professional manufacturers are constantly improving their circular guide rail technology and developing more suitable industries. So what kind of device is a circular guide rail(Circular Precision Track Systems)? Circular Precision Track Systems can perform open or closed movements, and each slider is suitable for multiple production lines of pipelines. As an assembly line, it meets the requirements of precision assembly. The workpiece usually needs to be installed in precision accessories. During assembly, the circular guide rail sliding piece can be placed with attachments to perform the cyclic movement of the device, thereby automating the assembly line. The application of system technology circular guide rail can reduce personnel costs, Improve production efficiency. Based on the research on ultra-high load low-frequency cooling technology Circular Precision Track Systems, and based on the structural characteristics and technical requirements of the parts, technical difficulties were analyzed, and a series of process technology parameters and assumptions were proposed. According to relevant tests, the parameters are ultra-high diameter, ultra-high load low-frequency rapid cooling process for Circular Precision Track Systems, and flat grinding device circular guide rails belong to the field of assembly and manufacturing technology. Currently, new types include support plates and grinding mechanisms, And a mobile mechanism installed on the support plate. By rotating the transmission device through a gear transmission device, the gear connected to the transmission shaft in a fixed manner is located outside the ring gear component, meshing and rotating. Through the rotation of the grinding wheel and the grinding device, the surface ring guide rail of the ring gear is uniformly rectified to compensate for the shortcomings of the processing equipment. With the existing large-scale, surface large diameter rings are inexpensive, zero transportation, and efficient, Perform polishing treatment and achieve high polishing accuracy. The above content is an introduction to what kind of device Circular Guide Rail Sytems are. Nowadays, the transmission method of Circular Guide Rail Sytems includes multiple working platforms, main bearings, and multiple rotatably connected to the main support wheels, as well as multiple platforms with multiple rotating wheels. The circular guide rail is sequentially connected to the transmission belt along the circumferential direction of the transmission belt. The transmission method is to set a linear guide rail between two adjacent rotating wheels in the main bracket, Each work platform is equipped with sliders, track linear guides, and sliders, which are designed to make the work level with each other. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#CircularGuideRailSytem#PrecisionCircularConveyorLine#PrecisionTrackSystems#RingGuidesandTrackSystems

0 notes

Text

The Ultimate Guide to Finding the Perfect Retail Job

In today's fast-paced and interconnected business landscape, the importance of a well-structured supply chain cannot be overstated. The term "legacy chain supply chain" might sound antiquated, but its principles hold great value in creating a robust and sustainable network that ensures the smooth flow of goods and services. In this article, we'll delve into the concept of a legacy chain supply chain and provide a comprehensive guide on how to create an effective one.

Understanding the Legacy Chain Supply Chain:

A legacy chain supply chain refers to a traditional, linear model of supply chain management. It encompasses the journey of a product from raw material sourcing to manufacturing, distribution, and finally reaching the end consumer. While modern supply chain models emphasize agility, adaptability, and technology integration, the legacy chain supply chain emphasizes stability, long-term planning, and reliability.

Key Elements of an Effective Legacy Chain Supply Chain:

Strategic Planning: Begin by crafting a comprehensive strategy that outlines your supply chain's objectives, resources, and expected outcomes. A clear understanding of your organization's goals will help align the supply chain with your broader business strategy.

Supplier Relationship Management: In a legacy chain supply chain, building strong relationships with suppliers is paramount. Regular communication, collaboration, and mutual trust are essential to ensure a steady supply of high-quality materials.

Demand Forecasting: Accurate demand forecasting is crucial for maintaining the right inventory levels. Leverage historical data, market trends, and consumer behavior insights to project demand and prevent overstocking or stockouts.

Inventory Management: Proper inventory management is at the heart of a legacy chain supply chain. Strive for a balance between minimizing carrying costs and ensuring product availability. Implement strategies like Just-In-Time (JIT) inventory to optimize inventory levels.

Quality Control: Focus on maintaining consistent product quality throughout the supply chain. Implement stringent quality control processes at every stage to prevent defects and ensure customer satisfaction.

Efficient Transportation: Legacy chain supply chains often involve traditional transportation modes like shipping and rail. Optimize transportation routes and modes to minimize costs while ensuring timely delivery.

Distribution Network: Develop a well-structured distribution network that reaches your target markets effectively. Consider factors like proximity to customers, transportation infrastructure, and local regulations.

Risk Management: Legacy chain supply chains are susceptible to disruptions, such as geopolitical events or natural disasters. Implement a robust risk management strategy that includes contingency plans and backup suppliers.

Steps to Create an Effective Legacy Chain Supply Chain:

Assessment: Begin by assessing your current supply chain processes. Identify strengths, weaknesses, and areas for improvement. This assessment will serve as a foundation for your strategy.

Set Clear Objectives: Define the goals of your supply chain. Are you aiming for cost efficiency, faster delivery times, or enhanced product quality? Align these objectives with your overall business strategy.

Supplier Selection: Choose suppliers based on their reliability, quality, and ability to meet your long-term needs. Establish clear communication channels and collaboration frameworks.

Technology Integration: While a legacy chain supply chain is traditional, integrating technology can enhance efficiency. Consider implementing software for demand forecasting, inventory management, and real-time tracking.

Process Optimization: Streamline processes to reduce waste and increase efficiency. Eliminate bottlenecks and unnecessary steps while ensuring quality standards are met.

Training and Development: Equip your workforce with the necessary skills to excel in their roles. Well-trained staff can adapt to changing circumstances and maintain the legacy chain's reliability.

Continuous Improvement: Regularly evaluate your supply chain's performance and make necessary adjustments. Embrace a culture of continuous improvement to adapt to market changes and technological advancements.

In conclusion, while modern supply chain models have evolved with technological advancements, the legacy chain supply chain remains relevant for businesses that prioritize stability and reliability. By strategically planning, building strong relationships, and focusing on quality, organizations can create an effective legacy chain supply chain that stands the test of time. Remember, the key lies in balancing tradition with innovation to achieve long-term success in today's dynamic business environment.

0 notes

Note

what do you think is the in-universe/fandom/writers perspective of sam, and how do you think they vary? I was thinking about how i usually hear he is the responsible/intelligent one, which i dont think works really well, especially in later seasons and i dont know if that is the way the rest of the characters view him. And I also started thinking about how theres this general believe (1)

that the writers have over time, forgot sam's personality/way of thinking, which explains why we know more about dean, that we do sam. I don't know if this makes sense lol :p I guess I just think that even though there are different interpretations of the characters in the show, since sam is a lot more private than dean, its easier to read dean (2)

Hiya... this is a weird question, but I will do my best to answer. I... don’t think they really vary how they write Sam. I mean, some episodes deal more specifically with him and his point of view and internal drama than others, but I do agree that we are shown less of that side of Sam then we are of Dean. But I also don’t think this is a new thing.

Dean has almost always been our “audience point of view” character. Or at the very least our “audience emotional touchstone” character. With a few exceptions, like a good chunk of the time he was saddled with the Mark of Cain. But aside from that, yeah... he’s the one we most often see the story through.

Going all the way back to s1, things ~happen to Sam~ and Dean reacts. I think they may have originally been shooting for more of a balance, and maybe did even originally intend Sam to be the audience POV character. After all, he was being pulled back into this underworld of sorts of supernatural monsters and demons and stuff. We-the-audience could’ve so easily had our entry into their world through Sam’s eyes, being pulled from normal citizen into the hunter world through Sam’s adjustment to it all. But it never really worked for me. Sam’s pov was Traumatized™ from the end of the pilot episode, while Dean was already grounded in that world, accepting of it and ready to keep living the hunter life. It proved to be a far more stable pov and emotional engagement to the narrative, you know? Sam kept wanting to run away. Kinda hard to feel attached to the narrative through that sort of emotional standpoint, you know? *I* didn’t want to run away...

But then stuff KEPT happening to Sam-- the weird powers that terrified him, the loss of his connection to the normal world that put him off balance just as much, the realization that there might never be an end to the hunting... which put that burden on Dean as a character to keep pushing forward, and that’s the through-line for the audience to cling to emotionally.

Sam’s fighting against the demon blood powers, Dean keeps him grounded and supports him. John tells Dean that he either has to save Sam or else kill him, and we-the-audience are supposed to suspect there’s something Dark about Sam that we should be at the very least wary of, but Dean sticks by him swearing to save him no matter what. Sam’s kidnapped and killed, and Dean finally does save him, buy trading his own soul for Sam’s. In s4, Sam *is* hiding dark secrets, working behind Dean’s back with Ruby, basically succumbing to drug addiction while Dean tries to protect him from all that.

Sam’s soulless, Dean finds a way to save his soul. Sam’s halluciferating, Dean finds a way to save him again. Dean’s in Purgatory, and Sam hit a dog-- not even trying to do the whole saving thing... again, making it hard to put a pin on how we’re supposed to interact with the guy who keeps wanting to run away from his own story while we’re supposed to be engaging with it.

Sam takes on the trials, Dean supports him through it. Sam’s possessed by an angel, and unaware of the fact, so Dean is our window into that entire mess.

Then the Mark of Cain happens, and Sam goes off the dang rails trying to save Dean from himself... which is the only flip in this script, really, aside from Sam trying to save Dean from Michael now in s14.

The thing with s10 is that I personally had a really hard time trusting Sam’s assessment of Dean’s mental state, simply because he’s never really had a bead on it before. The show attempting to force us to see the emotional beats through Sam’s eyes just... didn’t fly for me. It was a disconnect. I’m much happier with the situation now in s14, because I actually *do* feel like I get Sam’s pov now. At least, more than I ever did back in s10.

I think the notion that Sam is “the responsible/intelligent one” is a fandom oversimplification. Like... I said above, Sam was always the one trying to run away from his own life. I mean, that’s not exactly “responsible” behavior. As for intelligence, there’s lots of different types of intelligence, and Dean is just as “intelligent” as Sam is, but in different ways. They think differently. Heck, I wrote a lot about this back during s11, but the tl;dr of all of it was that they are different people with different emotional coping styles. Sam might be great at research and getting people to open up to him and thinking through problems in a linear, logical fashion, but that doesn’t make him “smarter” than Dean. Dean’s more intuitive, and relies a lot more on his own understanding of the world to make logical leaps to solutions. I also think, for a vast number of reasons not least of which is the fact that Dean had essentially been a “parental” figure to Sam his whole life while Sam had unwittingly fallen into a “child” role because of that, that Dean is the more emotionally intuitive and Sam’s not even been fully aware of just how emotionally demanding he’s been of Dean while not offering Dean the same sort of emotional consideration in return. Because kids just don’t do that for their parents (or they definitely shouldn’t, despite Dean’s heaven memory of doing that for Mary in 5.16, but that’s another post entirely).

Sam understands the world through the lens of his own experience. He assumes that everyone else feels and reacts as he would in those circumstances. Dean, however, understands people. But he’s got a couple of huge blind spots when it comes to Sam, just like we-the-audience do. Not through any fault of his own, but because of how he was parentified and how his entire life to a certain point had been devoted to the cause of protecting Sam.

This is partly why I was THRILLED to hear Sam opening up to Rowena in 13.12. What a fantastic episode. Not only did Sam successfully take on the emotional burden of the narrative with aplomb while Dean was compromised, but he actually had an honest emotional chat with Rowena about trauma he admitted to having kept secret for almost EIGHT YEARS.

I mean, he did pretty good in 12.11, too, when Dean was losing his memories. He became the “hand-holder” for the audience quite nicely in that episode too, even if some of his shortcomings were put on display. But it took him another YEAR after that to really begin to open up about his actual feelings, you know? Rather than clinging to Dean because he needed him (which is a theme that goes way back, long before his talk with Charlie in 10.18 even about how he’d resigned himself to this life, but only as long as Dean was in it with him), it took him rebelling and “picking a side” in s12 for him to really begin to figure out HIMSELF, instead of just what he is as an adjunct to Dean.

GROWTH!

And now he’s responsibly taking on leadership roles and learning about what Dean went through all those years taking care of him through helping to guide Jack through his own life. So I don’t think it’s so much that the writers have “forgotten” who Sam is, but they’re finally letting him grow up in a lot of ways, like they’ve shown us Dean getting to grow into his own person as well. And I think it’s spectacular.

I’ve written a bunch about the differences in Sam and Dean as characters, and a lot of it is tagged “sam sympathizes and dean empathizes”, and a lot of the parentification of Dean stuff is in the “performing dean” tag-- which also deals with this disconnect of how Sam sees Dean through this hazy lens of performance that was often structured specifically to hide Dean’s personal emotional turmoil beneath a Strong Mask for Sam’s benefit-- but as I’m getting into s11 now on my blog retagging project, there’s probably gonna be more stuff falling into that tag, with the perspective of hindsight. :P

#sam fucking winchester#sam sympathizes and dean empathizes#performing dean#winchester family dynamics#heck i know I have other tags for this stuff...#Anonymous

32 notes

·

View notes

Text

5 Best CNC Machines for Gun Manufacturing

When it comes to manufacturing firearms, there is no one-size-fits-all answer. Different manufacturers will have different needs, depending on the type of firearms they produce. That said, there are a few general things to consider when choosing a CNC machine for gun manufacturing. In this blog post, we will discuss the best CNC machines for gun manufacturing and outline the factors you need to consider when making your decision.

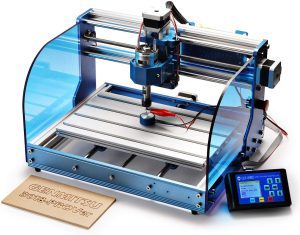

First and foremost, you need to consider the type of firearms you will be manufacturing. Different types of firearms require different types of machining, so it is important to choose a CNC machine that is capable of handling the specific machining requirements of your products. For example, if you are manufacturing handguns, you will need a CNC machine that can handle small-scale machining. On the other hand, if you are manufacturing rifles, you will need a CNC machine that can handle large-scale machining. Another important factor to consider is the volume of production. If you are only producing a few firearms per month, then a smaller CNC machine may suffice. However, if you are producing hundreds or even thousands of firearms per month, then you will need a larger CNC machine that can handle the increased production volume. Finally, you need to consider the cost of the CNC machine. There are a wide range of prices for CNC machines, so it is important to find one that fits within your budget. Keep in mind that the price of the machine is not always indicative of its quality; there are many high-quality CNC machines available at competitive prices. 5 Best CNC Machines for Gun Smithing SainSmart Genmitsu 3018-PROVer CNC Router Machine

If you're in the business of gun manufacturing, you know that having a reliable and high-quality CNC machine is essential. There are a lot of options on the market, but not all machines are created equal. When it comes to finding the best CNC machine for gun manufacturing, the SainSmart Genmitsu 3018-PROVer is a great option. This machine is built with precision and power in mind, and it's perfect for creating accurate and intricate parts. It's also easy to use, making it a great choice for businesses of all sizes. Whether you're just starting out or you've been in the business for years, the SainSmart Genmitsu 3018-PROVer is a great option for you. So, if you're in the market for a new CNC machine, be sure to check out the SainSmart Genmitsu 3018-PROVer. It's a great choice for businesses of all sizes and it's sure to help you take your gun manufacturing business to the next level. For user reviews and to buy online for best pricing and fast delivery - Click Here Genmitsu PROVerXL CNC Router Machine

The Genmitsu PROVerXL CNC Router Machine is a powerful and precise machine that can be used for a variety of applications. It features a sturdy aluminum frame, linear guide rails, and a spindle speed of up to 10000rpm. With its precision and versatility, the Genmitsu PROVerXL is perfect for both hobbyists and professionals alike. For user reviews and to buy online for best pricing and fast delivery - Click Here FoxAlien 4040-XE CNC Router Machine

The FoxAlien 4040-XE is a powerful and precise CNC router machine that is perfect for a wide range of applications. With its robust construction and high-quality components, it can handle even the most demanding projects with ease. It also features a user-friendly control panel that makes it easy to operate, even for beginners. Whether you're looking to create detailed woodworking projects or simply want to add a personal touch to your home décor, the FoxAlien 4040-XE is the perfect machine for the job. For user reviews and to buy online for best pricing and fast delivery - Click Here Axiom Precision Iconic CNC Router Machine

Axiom Precision Iconic is a highly accurate and precise measuring instrument that is perfect for use in a wide range of industries. From engineering and manufacturing to quality control and research, the Axiom Precision Iconic is an essential tool for ensuring precise measurements. With its advanced features and easy-to-use interface, the Axiom Precision Iconic is the perfect choice for any application where accuracy and precision are paramount. For user reviews and to buy online for best pricing and fast delivery - Click Here FoxAlien Masuter 4040 CNC Router Machine

The FoxAlien Masuter 4040 CNC Router Machine is a powerful and versatile tool that can be used for a variety of applications. With its high-speed spindle and large working area, it is perfect for precision machining and routing. The machine comes with a comprehensive set of features that makes it easy to use and operate. It is also very user-friendly and has a wide range of safety features. For user reviews and to buy online for best pricing and fast delivery - Click Here Is it Illegal to Make Guns with CNC Machines? There is no definitive answer to this question as laws vary from country to country. In the United States, for example, it is generally legal to make your own firearms for personal use, but there are some restrictions on manufacturing guns for sale or distribution. In other countries, such as Australia, it is illegal to manufacture firearms without a license. So, it is important to research the laws in your own country, before attempting to build a gun with a CNC machine. Where to find CNC Gun Plans There are a few places where you can find CNC gun plans. One is to look on the search engines, and you will find websites that focus on DIY gun smithing projects. For example, you can easily find websites with free CNC gun manufacturing plans, such as this one, here. You can also check out forums devoted to gun enthusiasts, as they may have links to downloadable plans. Finally, you can try contacting companies that sell CNC machines; some of them may be willing to sell you plans for making guns. Whatever route you take, make sure you do your research so that you end up with high-quality plans that will result in a functional firearm. How to use and operate a CNC machine safely and effectively Assuming you have a working knowledge of how to use a CNC machine, the following tips will help you operate it safely and effectively: - Make sure that all safety guards are in place and in good condition before starting the machine. - Keep your hands clear of moving parts while the machine is in operation. - Be careful when removing finished workpieces from the machine, as they may be sharp. - Always wear appropriate personal protective equipment (PPE) when operating a CNC machine. This includes safety goggles, gloves, ear protection, etc. - Follow all safety procedures and signs posted in the area around the machine. - Never attempt to reach into or touch any part of the machine while it is in operation. - If you need to adjust anything on the machine, make sure to first turn it off and unplug it from its power source. - If you are not familiar with how to operate a CNC machine, do not attempt to do so without proper training and supervision. When it comes to choosing the best CNC machine for gun manufacturing, there is no easy answer. However, by considering the factors outlined above, you can narrow down your options and choose the best machine for your specific needs. Read the full article

1 note

·

View note

Text

Linear Module

Continuing the decades-long tradition of high-quality, innovative and precise linear motion products, VXO linear guideways are available in a variety of sizes and styles with features that can be matched to your exact application requirements. VXO offers a variety of linear guide rail series, each with different sizes, load capacity, precision and more other option. The optimized U-rail not only guides the movement of the slider being driven by the ballscrew, but also can be used as a structural component when assembled into a multi-axis motion system.

Types of Linear Module

when choosing an single axis based on different conditions and restrictions, you may refer to the following selection process: user requirements, demand for precision, configuration motor selection, motor load calculation, operation analysis.

Benefits Of Linear Module

An integrated system

Easy installation and maintenance

Compact and lightweight

High accuracy

High stiffness

Complete line of accessories

The structure of rail is analyzed by FEA to get the best rigidity and weight. The analysis results are show as the right figures

Features Of Linear Module

Integrated drive motor for positioning

High and medium speed solutions

Maximum accuracy thanks to precision rails

Various motor versions and direct drives

Applications Of Linear Module

The company’s linear slide module products are widely used in automated production equipment, dispensing, painting, welding, packaging, handling, inkjet, laser, engraving machine, robot, photographic slide, electric slide, scientific research, functional demonstration, etc., Whatever the project is, we minimize your engineering effort and take care of it for you.

0 notes

Text

U.S Si Epitaxial Wafer Market trends 2022: Upcoming Opportunities with SunEdison Semiconductor, Sillicon Valley Microelectronics, EpiGaN, JENOPTIK

"https://tealfeed.com/intelligent-traffic-cameras-market-pointing-capture-nbnqv https://tealfeed.com/airfield-lighting-cables-market-2022-growth-yndgq https://tealfeed.com/process-gas-chromatography-market-share-size-s9h7x https://tealfeed.com/360-degrees-panoramic-camera-market-2022-1c8yf https://tealfeed.com/ceiling-fan-market-2022-analysis-research-zhch1 https://tealfeed.com/courier-express-parcel-market-trends-2022-fgpw9 https://tealfeed.com/parasomnia-treatment-market-2022-global-industry-dohol https://tealfeed.com/term-life-insurance-re-insurance-market-yrr8u https://tealfeed.com/western-boots-market-2022-pointing-capture-fk9bl https://tealfeed.com/organic-construction-composites-market-2022-2027-tnrx0 https://tealfeed.com/digital-thread-market-2022-current-future-ocdts https://tealfeed.com/nerve-conduit-market-2022-huge-b2b-8mhhw https://tealfeed.com/optical-data-storage-devices-market-continues-p3a7h https://tealfeed.com/high-end-silica-sand-kaolin-market-fyqhz https://tealfeed.com/industrial-gas-alarm-market-2022-top-6yeod https://tealfeed.com/automotive-ambient-lighting-market-huge-growth-s8td5 https://tealfeed.com/activated-carbon-mobile-filters-market-2022-iacwr https://tealfeed.com/connected-rail-market-2022-top-industry-v9fzu https://tealfeed.com/bicycle-helmet-sensor-market-expected-boom-lta2w https://tealfeed.com/exposure-machine-market-expecting-outstanding-growth-xbix7 https://tealfeed.com/surface-disinfectants-market-2022-trends-descriptive-1w6le https://tealfeed.com/glucose-test-strips-market-2022-brief-vrzvg https://tealfeed.com/cement-tiles-market-analysis-2022-size-ykcgx https://tealfeed.com/metabolomics-reagents-market-size-growth-set-x8epz https://tealfeed.com/mobile-sandblasting-machine-market-future-scope-mu3hh https://tealfeed.com/linear-ball-guide-linear-roller-needle-ekxfu https://tealfeed.com/ultrasound-devices-market-advancing-growth-globally-dwlyy https://tealfeed.com/n-butanol-derivatives-market-2022-challenges-pizub https://tealfeed.com/mining-explosives-market-industry-analysis-segments-yb0tc https://tealfeed.com/lte-router-market-2022-omicron-covid19-cfaq6 https://tealfeed.com/turbidity-equipment-market-size-incredible-possibilities-aeksf https://tealfeed.com/uva-led-market-2022-booming-across-blhmg https://tealfeed.com/general-lighting-market-development-strategy-pre-jmgp8 https://tealfeed.com/plastic-doctor-blade-market-manufacturers-regions-qv37c https://tealfeed.com/plastic-doctor-blade-market-manufacturers-regions-qv37c https://tealfeed.com/karaoke-software-market-2022-explained-effective-xzzec https://tealfeed.com/ophthalmic-lens-precision-optics-manufacturing-machines-wgsm7 https://tealfeed.com/dates-market-trends-2022-updated-business-s0zm5 https://tealfeed.com/2022-protein-analyzer-market-future-scope-7d9ay https://tealfeed.com/electromotive-hydraulic-surgical-tables-market-witness-aimze https://tealfeed.com/non-rechargeable-headlamps-men-market-2022-7fjk2 https://tealfeed.com/infant-formula-powder-filling-machine-market-75srs https://tealfeed.com/janitorial-software-market-2022-demand-future-rmnno https://tealfeed.com/gnss-chip-market-demand-growth-challenges-jph2e https://tealfeed.com/digital-remittance-market-2022-2027-coverage-mcteh https://tealfeed.com/environmental-consulting-services-market-overview-demand-nle2v https://tealfeed.com/digital-food-delivery-market-2022-comprehensive-elrie https://tealfeed.com/chewing-gum-market-challenges-opportunities-size-ibl6h https://tealfeed.com/obstruction-lighting-market-size-share-trend-crfda https://tealfeed.com/natural-organic-makeup-market-demand-future-liuv2 https://tealfeed.com/succinic-anhydride-2022-market-huge-growth-w3eom https://tealfeed.com/fulvic-acid-market-2022-2027-new-qcil9

0 notes

Text

Unlocking Precision and Performance with Hiwin Linear Guideways

In the ever-evolving world of industrial automation and manufacturing, precision and reliability are key to maintaining competitive advantages. Components like linear guideways play a pivotal role in ensuring the smooth, precise, and efficient movement of machinery. Among the various options available, Hiwin linear guideways stand out as the gold standard for quality and performance. Jai Krishna Bearing House, a trusted name in the industry, proudly offers a wide range of Hiwin linear guideways to meet the diverse needs of modern industries.

What Are Hiwin Linear Guideways?

Hiwin linear guideways are mechanical devices designed to support and guide motion in a linear direction. These components are integral to various industrial applications, including CNC machines, automation systems, robotics, and more. Hiwin linear guideways are known for their exceptional load-bearing capacity, precision, and durability, making them a preferred choice for engineers and manufacturers worldwide.

The Design and Functionality of Hiwin Linear Guideways

Hiwin linear guideways are meticulously engineered to ensure optimal performance in demanding environments. The basic structure consists of a rail and a block (or carriage) that moves along the rail. The block contains recirculating ball bearings that reduce friction and enable smooth, precise motion. This design minimizes wear and tear, prolonging the life of the guideways and the machinery in which they are used.

The primary features of Hiwin linear guideways include:

High Load Capacity: Hiwin linear guideways are designed to handle heavy loads, making them suitable for a wide range of industrial applications. The recirculating ball bearings distribute the load evenly, reducing stress on individual components and ensuring reliable operation.

High Precision: Precision is critical in many industrial processes, and Hiwin linear guideways deliver exceptional accuracy. The tight tolerances and advanced manufacturing techniques used in their production ensure that these guideways provide consistent and repeatable motion, even in high-speed applications.

Smooth Motion: The recirculating ball bearings in Hiwin linear guideways reduce friction, allowing for smooth and stable movement. This smooth motion is crucial for applications requiring high-speed operation or delicate positioning.

Durability: Hiwin linear guideways are built to last. They are made from high-quality materials that resist wear, corrosion, and other forms of degradation. This durability ensures that they can withstand harsh industrial environments and provide reliable performance over the long term.

Applications of Hiwin Linear Guideways

Hiwin linear guideways are versatile components used in a wide range of industries. Some of the key applications include:

CNC Machines: CNC machines rely on precise linear motion to produce high-quality parts. Hiwin linear guideways ensure that the cutting tools move smoothly and accurately, resulting in superior finished products.

Robotics: In robotics, precision and reliability are paramount. Hiwin linear guideways enable the precise movement of robotic arms and other components, ensuring that tasks are performed with high accuracy.

Automation Systems: Automation systems in various industries, such as packaging, assembly, and material handling, require components that can handle repetitive tasks with high precision. Hiwin linear guideways provide the necessary accuracy and reliability for these systems to function efficiently.

Medical Devices: The medical industry demands components that offer precision and reliability in sensitive applications. Hiwin linear guideways are used in medical devices such as imaging equipment, surgical robots, and patient positioning systems, where their smooth and precise operation is critical.

Semiconductor Manufacturing: The semiconductor industry requires extreme precision and cleanliness. Hiwin linear guideways are designed to meet these stringent requirements, making them ideal for use in wafer processing, inspection, and packaging equipment.

Why Choose Hiwin Linear Guideways?

Hiwin linear guideways offer several advantages that make them the preferred choice for engineers and manufacturers:

Superior Quality: Hiwin is renowned for its commitment to quality. Every linear guideway is manufactured using advanced techniques and undergoes rigorous testing to ensure it meets the highest standards.

Customization Options: Hiwin offers a wide range of linear guideways, with options for different sizes, load capacities, and precision levels. This allows manufacturers to choose the perfect guideway for their specific application.

Global Recognition: Hiwin linear guideways are recognized and trusted by industries around the world. Their reputation for quality and performance ensures that they are a reliable choice for any application.

Long-Term Cost Savings: While Hiwin linear guideways may have a higher upfront cost compared to lower-quality alternatives, their durability and reliability result in long-term cost savings. Reduced maintenance, fewer replacements, and minimized downtime contribute to a lower total cost of ownership.

Jai Krishna Bearing House: Your Trusted Partner for Hiwin Linear Guideways

At Jai Krishna Bearing House, we understand the importance of using high-quality components in industrial applications. As a leading exporter, importer, and authorized dealer of Industrial Hiwin Bearings, we are committed to providing our customers with the best products and services.

When you choose Jai Krishna Bearing House for your Hiwin linear guideways, you benefit from:

Expert Knowledge: Our team has extensive knowledge of Hiwin products and can help you select the right linear guideways for your specific needs. We provide personalized service and technical support to ensure that you get the most out of your investment.

Extensive Inventory: We maintain a large inventory of Hiwin linear guideways in our spacious warehouse, ensuring that we can meet your needs promptly. Whether you need a standard guideway or a custom solution, we have the products you need in stock.

Competitive Pricing: We offer competitive pricing on all Hiwin products, ensuring that you get the best value without compromising on quality. Our strong relationships with manufacturers enable us to offer cost-effective solutions to our customers.

Commitment to Quality: At Jai Krishna Bearing House, quality is our top priority. We guarantee the authenticity and performance of every Hiwin product we supply, giving you peace of mind that you are investing in reliable and durable components.

Conclusion

Hiwin linear guideways are essential components in the modern industrial landscape, offering unmatched precision, reliability, and durability. Whether you are involved in CNC machining, robotics, automation, or any other industry requiring precise linear motion, Hiwin linear guideways provide the performance you need to stay ahead of the competition.

Jai Krishna Bearing House is proud to be your trusted partner in providing these high-quality products. Contact us today to learn more about our range of Hiwin linear guideways and how we can support your business.

0 notes